Electrical safety is a paramount concern in myriad environments, from homes to industrial settings. Ensuring that electrical systems function safely and efficiently requires rigorous attention to cable management. Poor cable management can lead to various hazards, including electric shocks, fires, and equipment damage. Therefore, securing cables properly with high-quality cable straps isn't just a practice—it's a necessity.

The Role of Secure Cable Management in Overall Electrical Safety

Effective cable management serves as a foundational element of electrical safety. Well-managed cables not only keep electrical circuits running smoothly but also prevent accidental disconnections, overheating, or short-circuiting. A well-organized system reduces the risk of trip hazards and makes maintenance tasks considerably easier, ensuring ongoing safety and efficiency.

Common Electrical Hazards Linked to Poor Cable Management

Poorly managed cables present several risks. The most common include insulation damage due to constant friction against sharp edges or surfaces, which could subsequently lead to electrical shorts. Over-bundled cables tend to overheat, increasing fire risks, while unsecured cables can cause tripping accidents, posing physical dangers to individuals.

Regulatory Standards and Guidelines for Electrical Safety

Various regulatory bodies have established guidelines and standards for maintaining electrical safety. These regulations aim to minimize associated risks by stipulating specific requirements for cable organization and protection. Adhering to standards set by organizations like OSHA (Occupational Safety and Health Administration) and NEC (National Electric Code) is essential to ensure workplace safety and compliance.

Understanding Cable Straps

Cable straps come in various forms, each designed for particular applications and benefits. Several types include:

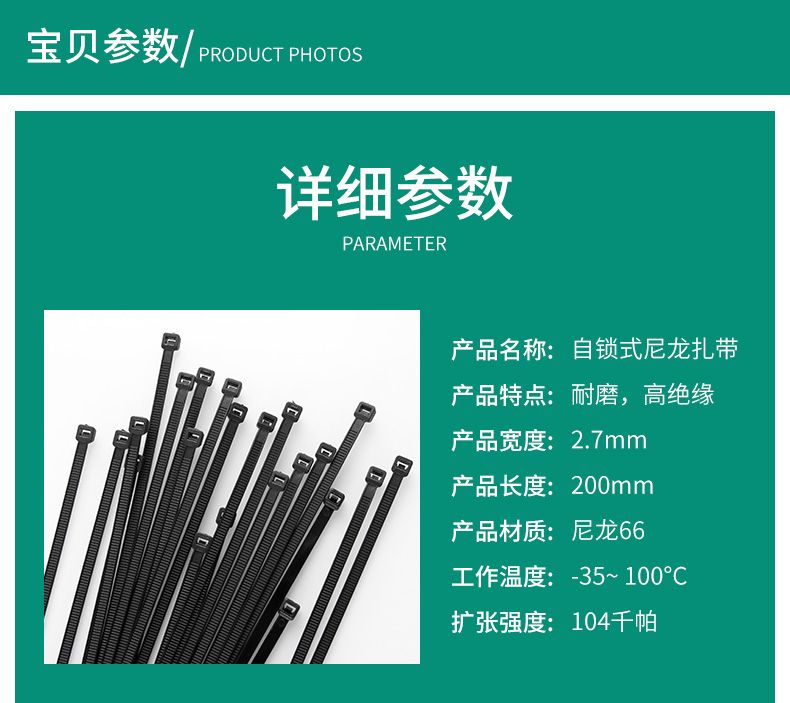

- Nylon cable ties: Widely used due to their versatility and strength. Available in multiple specifications, such as Guxin's self-locking nylon cable straps, they offer secure fastening options.

- Velcro straps: Ideal for temporary fixes and adjustments; easily reusable and gentle on cables.

- Stainless steel cable ties: Highly durable and resistant to extreme temperatures and corrosive environments, making them suitable for harsh conditions.

Comparing these materials highlights their unique properties: nylon provides flexibility and ease of use, velcro delivers convenience, and stainless steel offers unparalleled durability. It's crucial to choose high-quality cable straps to provide lasting solutions and safeguard your electrical setups effectively.

Best Practices for Using Cable Straps

Selecting the right cable strap depends on the application. For example, standard nylon self-locking ties work well for general uses, while heavy-duty stainless steel ties may be necessary for demanding environments. Securely fastening cables involves proper techniques such as avoiding over-tightening, which can damage cables, and ensuring no undue stress on wires. Placing straps at appropriate intervals enhances cable longevity and accessibility.

Regular inspection and maintenance of cable straps help detect wear and tear early, preventing potential hazards. Proactive replacement of old or damaged straps ensures continuous electrical safety.

Preventing Electrical Hazards

Diligently inspecting cables is vital. Look out for signs of potential damage, such as frayed insulation or exposed wires. In the event you find worn or broken cable straps, replace them immediately to maintain integrity. Prompt replacement of faulty straps helps avert serious technical issues and safety breaches.

Maintaining Functionality

Efficient organizing of cables improves overall system functionality. Clear labeling and color-coding enhance cable identification and streamline troubleshooting processes. Proper organization prevents tangling and kinks, reducing strain on connections and extending cable lifespan.

Case Studies and Real-World Applications

Industries ranging from IT and automotive to industrial manufacturing regularly employ robust cable management strategies. Successful implementations underscore the importance of meticulous cable arrangement. Organizations report safer working environments and increased operational efficiencies thanks to systematic cable strapping practices.

Tools and Accessories for Efficient Cable Management

A range of tools assist in the installation and maintenance of cable straps. Essential tools include cable tie guns for precise tensioning and wire cutters for trimming excess lengths. Additional accessories, such as cable mounts and sleeves, further support organized and efficient cable systems.

Expert Tips and Tricks

Professionals recommend following certain tips when optimizing cable strap usage. Avoid common mistakes such as overloading cable bundles, which increase heat buildup and risk. Implementing innovative solutions tailored to complex scenarios often involves custom-length straps or specialized mounting hardware.

FAQs and Troubleshooting

For those frequently asked questions about cable straps and electrical safety, here are some practical insights. Common issues like over-tightened straps causing cable damage can be circumvented through careful adjustment. Resources such as industry manuals and support forums provide additional guidance and troubleshooting assistance.

Conclusion

The significance of maintaining electrical safety with reliable cable straps cannot be overstated. Embracing best practices in cable management, regular inspections, and timely replacements uphold safety and functional efficacy. Investing time in mastering these techniques promises a more secure and efficient electrical setup, benefiting both users and systems alike.